- Description

- Structure

- Specification

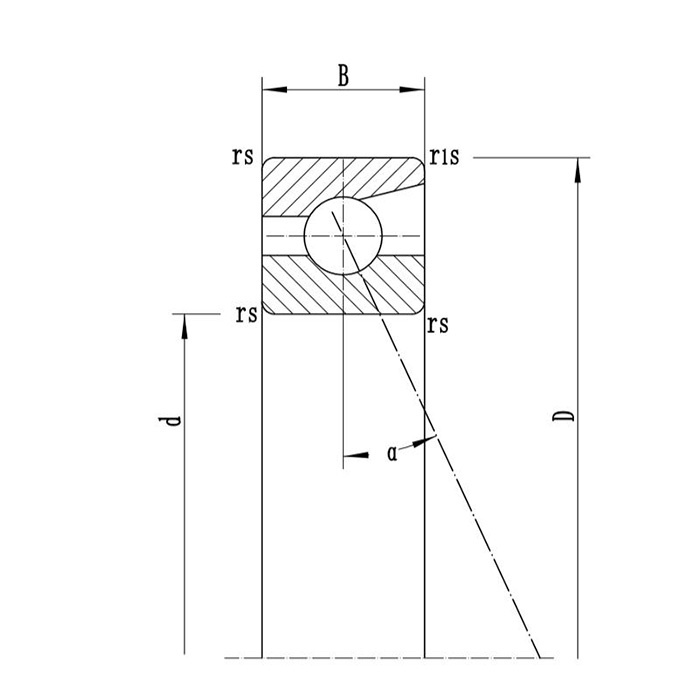

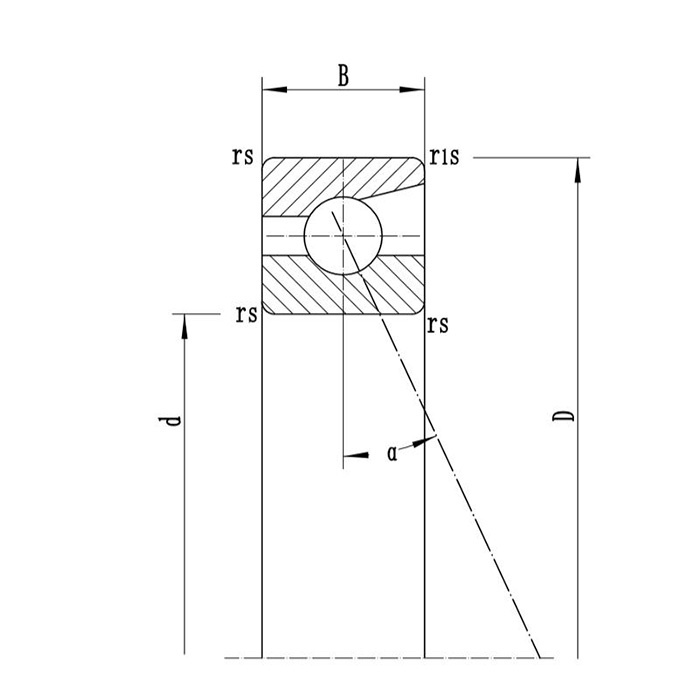

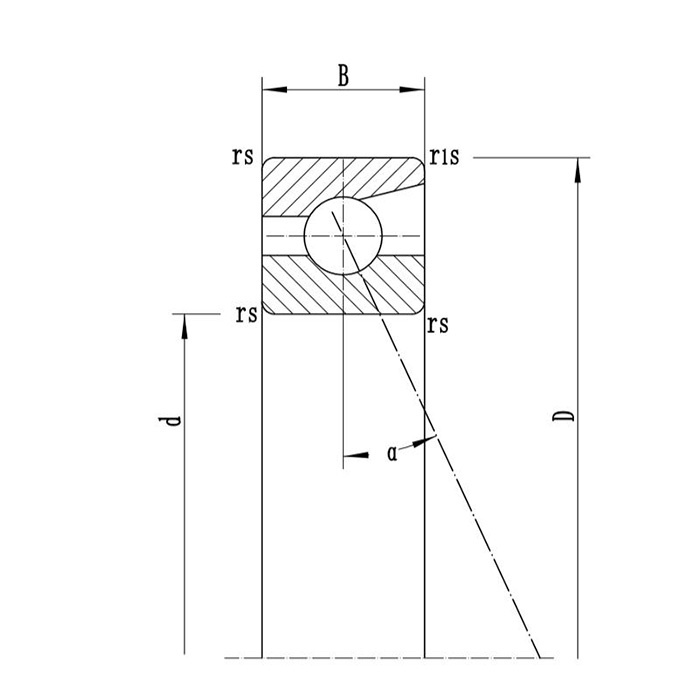

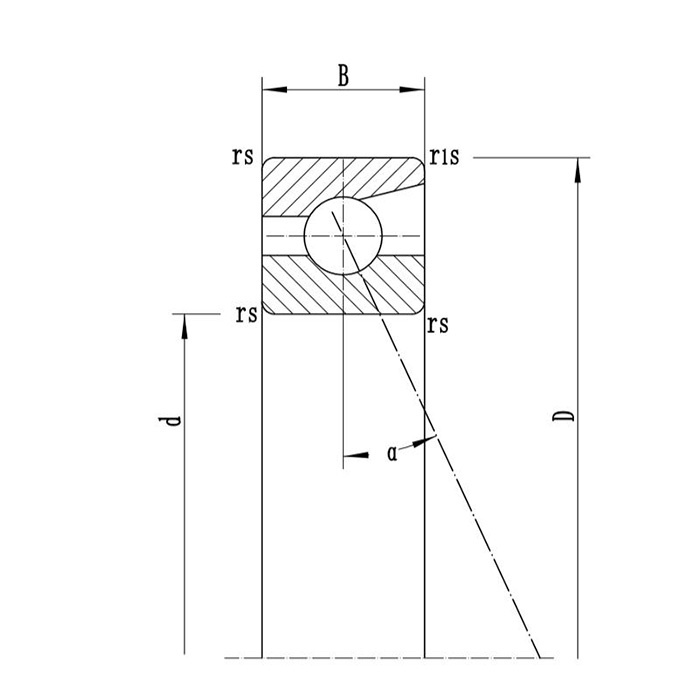

H70 Series Single Row Angular Contact Ball Bearing

Structural features:

Basic series YDPB precision bearing with ISO standard.

The contact angle include 15º and 25º, the paired use can bear both axial load and radial load or synthetic load.

Two types of cage:

The outer ring guided phenolic resin bakelite cloth cage and the rolling element guided nylon cage can be selected according to different uses.

For the middle-high speed working conditions, is recommended to use bakelite cage; 500000≤DmN≤1000000

For the low speed working conditions, can use nylon cage or bakelite cage.

Speed factor:

Outer ring guided phenolic resin bakelite cloth cage as standard

Grease lubrication DmN≤1000000 that the limiting speed N≤1000000/Dm Dm—Bearing mean diameter Oil (minimum quantity) lubrication DmN≤1500000

Applications:

This type of bearing has a wide application; Mainly used in high-speed precision axial positioning and radial positioning, and high precision rotation, etc.

For example:

CNC lathe spindle, various workpiece axis of grinding machine, grinding wheel spindle, photovoltaic slicer, vacuum pump, blower, precision transmission machinery and others.

Model Selection Installation and Maintenance

1. Please use the corrosion resistant bearings in a clean and dust free environment. The bearings should be carefully configured and the bearing spacer must be grounded. The inner and outer bearing spacers should have the same height and their depth of parallelism should be controlled to within 1µm.

2. Before installation wash and clean the angular contact ball bearing. After drying, lubricate the bearing with a specific amount of grease oil. If using oil mist lubrication, use it in moderation.

3. Special tools are required for installation. Exert the force evenly on the bearing, and don't hit it.

4. The single row ball bearing should be stored in a clean and ventilated place away from corrosive gas. The relative humidity of the environment should be no more than 65%, and regular rust protection is needed for long-term storage.

| HSS70 Series Sealed Angular Contact Ball Bearing |

| Model |

Boundary Dimensions |

〆 15o |

〆 25o |

Cage Material |

| d |

D |

B |

Load Rating |

Limiting Speed |

Load Rating |

Limiting Speed |

| Cr Cor |

Grease Oil |

Cr Cor |

Grease Oil |

| HSS7000 |

10 |

26 |

8 |

——— |

——— |

——— |

——— |

胶木 |

| HSS7001 |

12 |

28 |

8 |

——— |

——— |

——— |

——— |

胶木 |

| HSS7002 |

15 |

32 |

9 |

——— |

——— |

——— |

——— |

胶木 |

| HSS7003 |

17 |

35 |

10 |

6.7 4.9 |

44000 66000 |

6.4 4.7 |

39000 59000 |

尼龙 |

| HSS7004 |

20 |

42 |

12 |

9.6 6.3 |

37000 55000 |

9.2 6.0 |

33000 49000 |

尼龙 |

| HSS7005 |

25 |

47 |

12 |

12.9 8.7 |

33000 49000 |

12.3 8.3 |

29000 44000 |

尼龙 |

| HSS7006 |

30 |

55 |

13 |

15.7 11.6 |

27000 42000 |

14.9 10.9 |

23000 37000 |

尼龙 |

| HSS7007 |

35 |

62 |

14 |

19.3 17.5 |

19000 33000 |

10.4 10.3 |

19000 33000 |

尼龙 |

| HSS7008 |

40 |

68 |

15 |

19.9 19.1 |

18000 31000 |

18.9 18.2 |

16000 27000 |

尼龙 |

| HSS7009 |

45 |

75 |

16 |

26.7 25.3 |

16000 27000 |

25.4 24.1 |

15000 25000 |

尼龙 |

| HSS7010 |

50 |

80 |

16 |

27.6 27.5 |

15000 25000 |

26.2 26.2 |

14000 23000 |

尼龙 |

| HSS7011 |

55 |

90 |

18 |

36.7 37.1 |

13000 21000 |

34.8 35.3 |

12000 19000 |

尼龙 |

| HSS7012 |

60 |

95 |

18 |

37.8 40 |

13000 21000 |

35.8 38 |

11000 18000 |

尼龙 |

| HSS7013 |

65 |

100 |

18 |

38.9 42.9 |

12000 19000 |

36.8 40.7 |

10000 17000 |

尼龙 |

| HSS7014 |

70 |

110 |

20 |

49.9 55.5 |

11000 18000 |

47.2 52.7 |

9000 16000 |

尼龙 |

| HSS7015 |

75 |

115 |

20 |

51.3 59.2 |

10000 17000 |

48.5 56.2 |

8500 15000 |

尼龙 |

| HSS7016 |

80 |

125 |

22 |

61.6 70.4 |

9000 16000 |

58.3 66.9 |

8000 14000 |

尼龙 |

| HSS7017 |

85 |

130 |

22 |

63.6 75 |

8500 15000 |

59.9 71.3 |

7500 13000 |

尼龙 |

| HSS7018 |

90 |

140 |

24 |

66.9 84 |

8000 14000 |

63.2 79.7 |

7000 12000 |

尼龙 |

| HSS7019 |

95 |

145 |

24 |

79.1 97.6 |

7500 13000 |

74.8 92.7 |

6500 11000 |

尼龙 |

| HSS7020 |

100 |

150 |

24 |

81.2 103.3 |

7000 12000 |

76.7 9.8 |

6000 10000 |

尼龙 |

| HSS7021 |

105 |

160 |

26 |

93.9 118.2 |

6500 11000 |

88.8 112.2 |

6000 10000 |

尼龙 |

| HSS7022 |

110 |

170 |

28 |

110.4 139.8 |

6000 10000 |

104.4 132.8 |

5700 9000 |

尼龙 |

| HSS7024 |

120 |

180 |

28 |

112.7 148.7 |

6000 10000 |

106.3 141.1 |

5700 9000 |

尼龙 |

| HSS7026 |

130 |

200 |

33 |

144.8 190.8 |

5700 9000 |

136.8 181.0 |

5000 8000 |

尼龙 |

| HSS7028 |

140 |

210 |

33 |

148.7 202.6 |

5000 8000 |

140.4 192.2 |

4600 7500 |

尼龙 |

| HSS7030 |

150 |

225 |

35 |

168.4 232.5 |

4600 7500 |

159.1 220.6 |

4000 6500 |

尼龙 |

| HSS7032 |

160 |

240 |

38 |

189.1 264.5 |

4000 6500 |

178.6 251.0 |

3800 6000 |

尼龙 |

| HSS7034 |

170 |

260 |

42 |

205.6 299.3 |

3800 6000 |

194.2 284.0 |

3300 5300 |

尼龙 |

| HSS7036 |

180 |

280 |

46 |

229.5 352.1 |

3500 5700 |

216.8 334.1 |

3000 5000 |

尼龙 |

| HSS7038 |

190 |

290 |

46 |

235.1 370.8 |

3300 5300 |

222.1 351.8 |

2800 4600 |

铜 |

| HSS7040 |

200 |

310 |

51 |

289.1 471.4 |

2800 4600 |

273.1 447.3 |

2600 4300 |

铜 |

| HSS7044 |

220 |

340 |

56 |

338 445 |

2500 3700 |

319 440 |

2400 3500 |

铜 |

| HSS7048 |

240 |

360 |

56 |

345 490 |

2200 3300 |

325 465 |

2100 3100 |

铜 |

| HSS7052 |

260 |

400 |

65 |

346 490 |

2201 3300 |

326 465 |

2101 3100 |

铜 |

| HSS7056 |

280 |

420 |

65 |

347 490 |

2202 3300 |

327 465 |

2102 3100 |

铜 |

| HSS7060 |

300 |

460 |

74 |

348 490 |

2203 3300 |

328 465 |

2103 3100 |

铜 |

| HSS7064 |

320 |

480 |

74 |

349 490 |

2204 3300 |

329 465 |

2104 3100 |

铜 |

| HSS7068 |

340 |

520 |

82 |

350 490 |

2205 3300 |

330 465 |

2105 3100 |

铜 |

| HSS7072 |

360 |

540 |

82 |

351 490 |

2206 3300 |

331 465 |

2106 3100 |

铜 |

| HSS7076 |

380 |

560 |

82 |

352 490 |

2207 3300 |

332 465 |

2107 3100 |

铜 |

| HSS7080 |

400 |

600 |

90 |

353 490 |

2208 3300 |

333 465 |

2108 3100 |

铜 |

| HSS7084 |

420 |

620 |

90 |

354 490 |

2209 3300 |

334 465 |

2109 3100 |

铜 |

Consultation

Consultation