CRB Crossed Roller Bearing Description

This series Crossed Roller Bearing is mainly consisted of an outer ring, an inner ring, a plurality of rollers and aplurality of spacers. The roller lies between the inner ring and the outer ring. The spacer is placed between rollers to prevent the mutual friction between rollers so as to decrease the torque resistance for rotation. In addition, thesurface of the roller and the rolling track is linear contact. So, when the bearing is loaded, the loading area will bevery large. Thus, the elastic deformation will be less, and the bearing will achieve a long service life. Each roller in Crossed Roller Bearing is crossed at 90 angle, which is able to bear the loading force from axial, radial and the other direction at the same time.

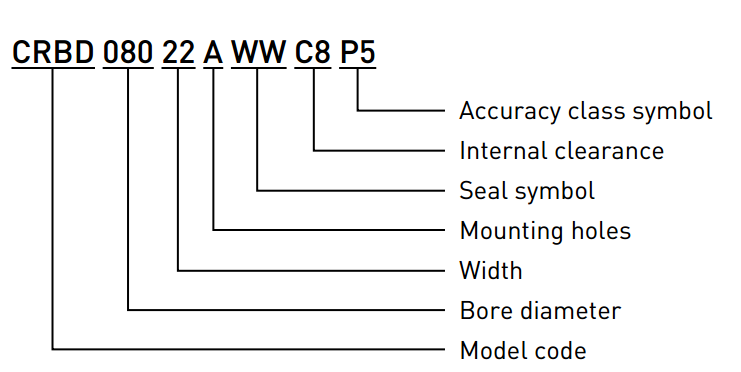

Model intruction

Remark :

Remark :

1.Mounting holes symbol. With blank space means the bearing without mounting hole. A is represented the bearing with mounting screw holes,while B is symbolized the bearing with same direction mounting sinkholes, and C is symbolized the bearing with opposite direction mounting sink holes.

2.WW: Seal symbol. WW signifies the seals at both sides. NN signifies the open type without seals. Both types have oil holes for lubrication.

3.C8: Axial internal clearance classification. C1 signifies positive clearance with less friction force, while C8 signifies negative clearance without backlash, which will result in increase of friction force by unloading condition.

Product Features

1. High loading capacity

2. High rigidity

3.High accuracy for dimension and rotation .

4. Taking loads from all directions at the same time.

5. Smooth rotation

6. Small volume, space saving

7. Easy installation and adjustment

8. Various bearing types and dimensions for your requirements

9. Providing customized design

Types of Crossed Roller Bearing

CRBE series:with flanged holes high rigidity,consist of flanged hole of one inner ring and outer ring, can be mounted directly ,suitable for inner ring or outer ring rotate.

Structure of sealed type and open type

1. Sealed type: The seal has very good sealing effect, which is able to effectively prevent the foreign substancefrom entering the track, and prevent the lubricant leaking from the track. In addition, the seal has oil holes forlubricating.

2. Open type: There is no seal. The friction resistance is smaller. It is suitable for the use of low torque. The opentype also has oil holes for lubricating

Installing steps

Upon installation of the Crossed Roller Bearing, please follow:

1. Inspect parts before installing: Clean bearing bracket, main axle or other parts to remove dirt or grease

2. Place the bearing into bearing bracket and main axle: As for the design of clearance match, keep the bearinghorizontally and insert the bearing into bearing bracket or axle. If it is hard for the installation, use a rubberhammer to slightly hit every part of bearing, so that the bearing can be inserted into bearing bracket or axleeasily. Finally, the sound change is used to confirm the match of bearing and basic face. As for the design ofinterference match, Use heating or cooling way to expand or shrink the parts for ease of installation. But thebearing temperature should not be over 80℃C. In addition, it has to pay attention to the hitting force to thebearing, if the force is too large, the bearing may be damaged. If the inner ring or outer ring of split bearing isacentric, the bolt of inner ring or outer ring can be loosen slightly. Then, turn the outer ring or inner ring up or placing the bearing into bearing bracket, so that the bearing can be placed into bearing bracket smoothly.

3.Install mounting disc: Place the mounting disc on the bearing, and align the screw hole for locking the bolt.Tighten the bolts diagonally as follow diagram. Then tighten all bolts in sections. Prevent to tighten all bolts at at ime.

Description of lubrication

1. There is lubricant in all Crossed Roller Bearings. So, the delivered bearing can be used directly, If the lubrication is insufficient, the friction resistance will be increased and the service life will be reduced. The lubricant should be supplemented for the open bearing periodically, such as 1 -6 months

The lubricating frequency depends on the use condition- Installation sequence,The lubricant should be distributed evenly inside the bearing.

2.Prevent to mix different lubricants

3. If the bearing is used at high vibration, clean room,vacuum, high temperature or low temperature, thespecific lubricant should be used, please contact with YDPB

Use cautions

1.The normal use temperature of bearing is 10-80℃,If it is over this temperature range, please contact with YDPB.

2. If foreign substance enters into inside structure of bearing, the rotation route of roller may be damaged, even the bearing may fail. So, prevent the foreign substance enters into inside structure of bearing.

3. If foreign substance enters into inside structure of bearing, please clean it then refill the lubricant.

4. Please do not remove the bolt and nut of split bearing. Upon installing, please do not apply force to the bolt and nut.

| Bearing No. | Dimensions (mm) | Dimensions of mounting holes (mm) | Basic loading rates (kN) |

Abutment and fillet dimensions (mm) |

|||||||||

| Inner dia. (d) |

Outer dia. (D) |

Width (B, T) |

Chamfer (r min) |

Oil holes d OH |

Inner rings | Outer rings | Dynamic load, C |

Static load, C0 |

da | Da | |||

| PCD1 | Mounting holes | PCD2 | Mounting holes | ||||||||||

| CRBE 02012 A | 20 | 70 | 12 | 0.6 | 3 | 28 | 6-M3 through | 57 | 6-ø3.4 throughø6.5 counter bore depth 3.3 | 8.26 | 9.16 | 35 | 47 |

| CRBE 03515 A | 35 | 95 | 15 | 0.6 | 3 | 45 | 8-M4 through | 83 | 8-ø4.5 through ø8 counter bore depth 4.4 | 18.9 | 23.4 | 57 | 73 |

| CRBE 05515 A | 55 | 120 | 15 | 0.6 | 3 | 65 | 8-M5 through | 105 | 8-ø5.5 through ø9.5 counter bore depth 5.4 | 21.7 | 30.6 | 77 | 92 |

| CRBE 08022 A | 80 | 165 | 22 | 1 | 3 | 97 | 10-M5 through | 148 | 10-ø5.5 through ø9.5 counter bore depth 5.4 | 40.4 | 63.6 | 117 | 132 |

| CRBE 08022 B | 80 | 165 | 22 | 1 | 3 | 97 | 10-ø5.5 throughø9.5 counter bore depth 5.4 | 148 | 10-ø5.5 through ø9.5 counter bore depth 5.4 | 40.4 | 63.6 | 117 | 132 |

| CRBE 08022 C | 80 | 165 | 22 | 1 | 3 | 97 | 10-ø5.5 throughø9.5 counter bore depth 5.4 | 97 | 10-ø5.5 through ø9.5 counter bore depth 5.4 | 40.4 | 63.6 | 117 | 132 |

| CRBE 09025 A | 90 | 210 | 25 | 1.5 | 3 | 112 | 12-M8 through | 187 | 12-ø9 through ø14 counter bore depth 8.6 | 46 | 80.2 | 139 | 157 |

| CRBE 09025 B | 90 | 210 | 25 | 1.5 | 3 | 112 | 12-ø9 through ø14 counter bore depth 8.6 | 187 | 12-ø9 through ø14 counter bore depth 8.6 | 46 | 80.2 | 139 | 157 |

| CRBE 09025 C | 90 | 210 | 25 | 1.5 | 3 | 112 | 12-ø9 through ø14 counter bore depth 8.6 | 187 | 12-ø9 through ø14 counter bore depth 8.6 | 46 | 80.2 | 139 | 157 |

| CRBE 11528 A | 115 | 240 | 28 | 1.5 | 3 | 139 | 12-M8 through | 217 | 12-ø9 through ø14 counter bore depth 8.6 | 73.1 | 131.9 | 168 | 188 |

| CRBE 11528 B | 115 | 240 | 28 | 1.5 | 3 | 139 | 12-ø9 through ø14 counter bore depth 8.6 | 217 | 12-ø9 through ø14 counter bore depth 8.6 | 73.1 | 131.9 | 168 | 188 |

| CRBE 11528 C | 115 | 240 | 28 | 1.5 | 3 | 139 | 12-ø9 through ø14 counter bore depth 8.6 | 217 | 12-ø9 through ø14 counter bore depth 8.6 | 73.1 | 131.9 | 168 | 188 |

| CRBE 16035 A | 160 | 295 | 35 | 2 | 6 | 184 | 12-M10 through | 270 | 12-ø11 through ø17.5 counter bore depth 10.8 | 102 | 192.3 | 218 | 238 |

| CRBE 16035 B | 160 | 295 | 35 | 2 | 6 | 184 | 12-ø11 through ø17.5 counter bore depth 10.8 | 270 | 12-ø11 through ø17.5 counter bore depth 10.8 | 102 | 192.3 | 218 | 238 |

| CRBE 16035 C | 160 | 295 | 35 | 2 | 6 | 184 | 12-ø11 through ø17.5 counter bore depth 10.8 | 270 | 12-ø11 through ø17.5 counter bore depth 10.8 | 102 | 192.3 | 218 | 238 |

| CRBE 21040 A | 210 | 380 | 40 | 2.5 | 6 | 240 | 16-M12 through | 350 | 16-ø14 through ø20 counter bore depth 13 | 142 | 286.2 | 277 | 299 |

| CRBE 21040 B | 210 | 295 | 35 | 2 | 6 | 240 | 16-ø14 through ø20 counter bore depth 13 | 350 | 16-ø14 through ø20 counter bore depth 13 | 142 | 286.2 | 277 | 299 |

| CRBE 21040 C | 210 | 295 | 35 | 2 | 6 | 240 | 16-ø14 through ø20 counter bore depth 13 | 350 | 16-ø14 through ø20 counter bore depth 13 | 142 | 286.2 | 277 | 299 |

Consultation

Consultation